Vacuum Planetary Mixer

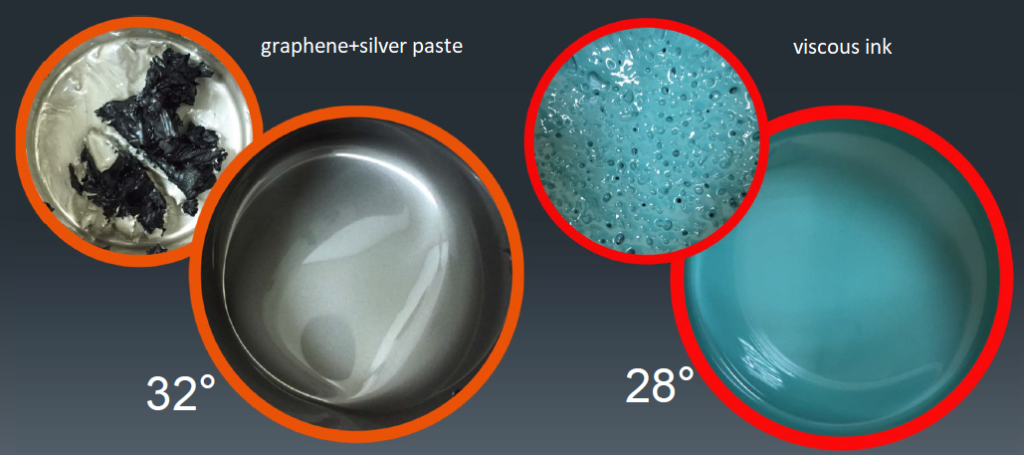

This mixer combines vacuum pressure reduction function with user-defined rotation and revolution. It enables efficient mixing with the elimination of submicron-level air bubbles. With rotation and revolution movement under vacuum pressure reduction, mixing is made simple especially for high viscosity materials. The processing time can be further reduced compared to the atmospheric mixer.

It is ideal for a wide variety of material for different industries including passive components, LED, PCB, touch panel, LCD panel, solar panel, semiconductor, medical supplies, printing, automobile, and etc.

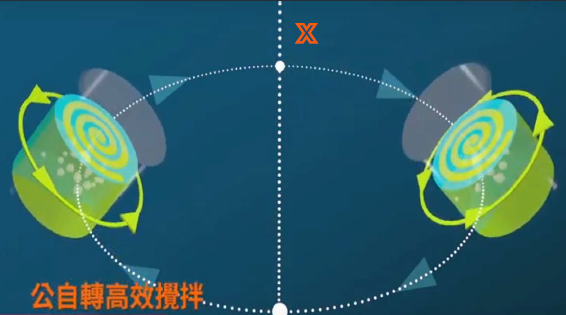

Planetary Mixing Principle

The vacuum planetary mixer is a device that can agitate liquid materials without using any agitator blades and remove sub-micron level air bubbles simultaneously.

The mixing action comprises the following:

(1) Revolution: The centrifugal force moves the material away from center.

(2) Rotation: The rotation causes flow of the material with rotation and shearing.

(3) Tilting: A 45 degrees tilting of the rotational axis results in a three-dimensional fluid flow.

Key Features

- Dual motor with high torque to handle the mixing of heavy material well.

- Vacuum mixing allows removal of sub-micron level air bubbles

- No agitating blades

- Up to 20 set of preset parameters for easy operation

- Safety monitoring for abnormal vibration, vacuum, and motor operation

Download the White paper here: https://www.pinnacle-techpro.com/wp-content/uploads/2025/02/PTL_mixer_whitepaper.pdf